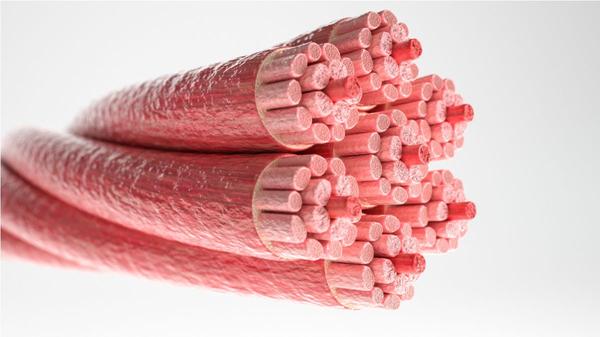

Clothes created with these synthetic muscle fibers would be more resistant than Kevlar

Categrimage

They could also be used to manufacture protective equipment, biomedical implants and prostheses

A team of researchers from the University of Washington used bacteria to produce synthetic muscle proteins, which can then be fiber to make clothes.

Imitate nature

Man is able to make artificial materials for any use, but generally, nature having several billion years ahead, work has already been done, and with a better result.Muscles are an example: artificial muscles made from materials such as polymers, rubber and carbon fiber have proven to be solid, but can be complicated to produce and are often overpasted by their natural equivalents.

Lire aussi Does coffee really increase the desire to defecate?For these new works published in the journal Nature Communications, the researchers therefore decided to use a significantly different approach."We wondered why we did not directly manufacture synthetic muscles," explains Fuzhong Zhang, principal author of the study."Obviously, we were not going to harvest them on animals and we are therefore turned to bacteria.»»

Natural muscles are made up of three main proteins.The team focused on one of them, known as Titine, acting as a spring and giving muscle its elasticity.

Greater known protein, it is however difficult to artificially assemble.In order to overcome this obstacle, the team has developed bacteria capable of producing large proteins from small segments.Thanks to a damp spinning technique, the researchers obtained titine fibers 10 micrometers wide.

Lire aussi A cocktail of medicines has rejected adult frog legsImpressive properties

The fibers obtained have proved to be resistant and solid, but always flexible, and capable of dissipating mechanical energy in the form of heat.According to the team, such properties make it possible to envisage the use of the material, which would prove in this regard more resistant than the Kevlar, to manufacture protective equipment such as the bulletproof vests.Being composed of the same protein as natural muscle fibers, it should also be biocompatible, which makes it possible to envisage different applications in the medical field (sutures, implants, prostheses).

« Les fibres musculaires naturelles, dont la production se révèle bon marché et évolutive, pourraient permettre de répondre plus efficacement à de nombreuses problématiques existantes»», souligne Zhang.

As part of future work, the team claims that the bacteria assembler of protein could be used to make other types of polymers for a whole series of applications.

Lire aussi Vitamin D reduces the risk of autoimmune disease by 22 % Source : New AtlasParYann Contegat, le 11 septembre 2021 Yann Contegat